Tour I. Beckley Furnace

It’s Like a Furnace in Here!

East Canaan (Google maps location)

October 5, 2008

[Note: This is merely a copy of the write up on the Museums page.]

An absolutely brilliant and beautiful Fall day in Connecticut. Grandmom and Granddad up from Delaware watching Damian back in West Hartford (as he napped whoop-de-doo). Hoang and I take a leisurely drive west on Route 44 through some of the prettiest October scenery on the earth. We visit a bucolic vineyard and winery. We kiss. We hold hands. We rustle through the fallen leaves and listen to the gurgling mountain stream.

An absolutely brilliant and beautiful Fall day in Connecticut. Grandmom and Granddad up from Delaware watching Damian back in West Hartford (as he napped whoop-de-doo). Hoang and I take a leisurely drive west on Route 44 through some of the prettiest October scenery on the earth. We visit a bucolic vineyard and winery. We kiss. We hold hands. We rustle through the fallen leaves and listen to the gurgling mountain stream.

We go to Connecticut’s only designated Industrial Monument, Beckley Furnace. We are awesome. Just look at the joy on our faces in the pictures!

So… as the sign at the Furnace site asks, “What was this place?” The Beckley Blast Furnace was one of three blast furnaces in operation along Lower Road and the Blackberry River in East Canaan during the period 1832-1923. It was built in 1847 by John Adam Beckley, great-grandson of Esquire Samuel Forbes and grandson of John Adam, Jr., the founders of the Forbes & Adam Iron Company. It was acquired by the Barnum & Richardson Company in 1858.

Beckley Furnace (known as “East Canaan #2″ during the Barnum and Richardson years) produced pig iron until the winter of 1918-19.

Beckley Furnace (known as “East Canaan #2″ during the Barnum and Richardson years) produced pig iron until the winter of 1918-19.

Constructed of locally quarried marble, the furnace was originally thirty-two feet in height and thirty feet square at the base. Later, after it was acquired by the Barnum Richardson Company, the height was raised to forty feet making it one of the largest of forty-three blast furnaces in the Salisbury Iron District.

In April 1896, fire destroyed many of the wood buildings at Beckley. When the operation was put back in blast in 1898, brick had replaced wood in the support structures near the furnace, particularly those above the charging wall. In the winter of 1919, with World War I over a resultant decline in demand for iron, the Beckley Furnace was finally closed. However, nearby East Canaan #3 (the so-called “Furnace in a Field”) did not go out of blast until 1923. A fourth blast furnace, East Canaan #4, was still under construction at the time, was never in blast, and no trace remains of it today.

In April 1896, fire destroyed many of the wood buildings at Beckley. When the operation was put back in blast in 1898, brick had replaced wood in the support structures near the furnace, particularly those above the charging wall. In the winter of 1919, with World War I over a resultant decline in demand for iron, the Beckley Furnace was finally closed. However, nearby East Canaan #3 (the so-called “Furnace in a Field”) did not go out of blast until 1923. A fourth blast furnace, East Canaan #4, was still under construction at the time, was never in blast, and no trace remains of it today.

Now, if you’re like me, that made little to no sense. So let’s get some local history of this western area of the state. Iron Forges came early to the Blackberry River, with the first Catalan forge built in 1739 downstream from the Beckley site. A young man named Samuel Forbes (1729-1827 – wow!) developed the iron industry out here. Drawing on the high quality ore from nearby Salisbury, limestone from local quarries and charcoal made from the surrounding hardwood forests, the forges and furnaces of East Canaan were to play a major rle in the development of the nation’s iron industry.

Now, if you’re like me, that made little to no sense. So let’s get some local history of this western area of the state. Iron Forges came early to the Blackberry River, with the first Catalan forge built in 1739 downstream from the Beckley site. A young man named Samuel Forbes (1729-1827 – wow!) developed the iron industry out here. Drawing on the high quality ore from nearby Salisbury, limestone from local quarries and charcoal made from the surrounding hardwood forests, the forges and furnaces of East Canaan were to play a major rle in the development of the nation’s iron industry.

Forbes quickly became a leader in the industry, standardizing sizes for orders as far away as Philadelphia. During the Revolutionary War, Forbes made cannons for the effort at his Lakeville forge. Later, he developed machines to make nails and knives more efficiently and played a vital role in beating the British. His early foundations laid the groundwork for the booming 19th century iron industry in the area.

Enter Beckley Furnace. By the mid to late 19th century, this thing was in full operation (along with several others in the area). Here, using the dammed up Blackberry River to run air blasts, high quality iron ingots were produced and sent to nearby Lime Rock for processing into iron products.

Details

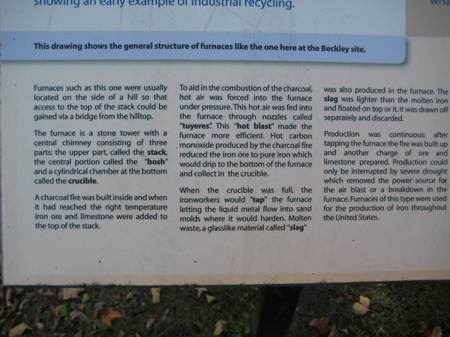

Want more details? The iron ore, charcoal and limestone were dumped into the top of the continuously operating furnace. Oxygen made the fire burn hotter, so heated air blasts were forced into the mixture through nozzles called tuyeres, located in the archways of the furnace. With intense heat, the iron was melted and drawn off through an opening in the casting (main) arch. This molten iron flowed into large forms molded in the earth, known as sows, and from there into smaller ingot sized forms known as pigs. By a separate operation, the impurities called slag, were drawn off and discarded.

Massive slag piles can be found across the river, apparently. In 1920, the slag heap was estimated at 900,000 cubic yards! Much of it was crushed with cement to make slag concrete.

Massive slag piles can be found across the river, apparently. In 1920, the slag heap was estimated at 900,000 cubic yards! Much of it was crushed with cement to make slag concrete.

And by the way, the ingots got their name from the fact that the shape of the molds resembled piglets nursing on their mother. One particular use of the iron made here was railroad car wheels; those made from iron produced here were particularly resistant to cracking.

There are a ton more details regarding iron production; some you can read in the accompanying pictures. I did want to mention one last bit I found interesting: Salamanders.

Salamanders are large chunks of solid iron that form inside the hearths of furnaces. These happened due to many reasons, never good ones. When they formed, it caused a costly shut down so that the hearth could be rebuilt and the iron chunk removed.

Here is a picture of a Beckley salamander I found

At least 13 salamanders have been found in the Beckley area; notably there is a huge one across the road on the way out – but I neglected to take a picture. I remember thinking, “Hm, that’s neat. Wonder what that is?” and driving onward.

Now that we have a taste of old timey ironworks, what else can we do? Lots. The Beckley site has a little learning center that used to be the paymasters headquarters. They put on programs on Saturday mornings during the summer as well as Blackberry River walks from time to time. There are also several museums out there with much more on the former iron industry; these are mostly in Kent, Sharon and Salisbury.

Now that we have a taste of old timey ironworks, what else can we do? Lots. The Beckley site has a little learning center that used to be the paymasters headquarters. They put on programs on Saturday mornings during the summer as well as Blackberry River walks from time to time. There are also several museums out there with much more on the former iron industry; these are mostly in Kent, Sharon and Salisbury.

But that’s not all we have to look forward to! There is a program called the Iron Heritage Trail! This is a massive 58 site trail encompassing sites in NY and MA as well as our own Connecticut comprising over half the sites. Some sites are merely “former†sites, but I’ll figure it out as I complete it. The Beckley Furnace is the center/showpiece of the trail and comprises the entire first “Tour.”

This trail’s web presence is confusing and lacking. Undaunted, I contacted the Salisbury (CT) Town Historian, Katherine Chilcoat, who sent me an excellent brochure and map of the trail. It is published by the Upper Housatonic Valley Heritage Area and appears to be a work in progress.

This trail’s web presence is confusing and lacking. Undaunted, I contacted the Salisbury (CT) Town Historian, Katherine Chilcoat, who sent me an excellent brochure and map of the trail. It is published by the Upper Housatonic Valley Heritage Area and appears to be a work in progress.

Between the Lakes seems to be be helping in developing the Trail and I found Limerock’s Trinity Episcopal Church has some association. Trinity Church is the oldest structure built by the iron industry that is still under the same ownership and still in use for its original purpose!

There are 9 separate tours; 5 of which are wholly in Connecticut and a sixth with has a couple New York stops we’ll be skipping. Check it out.

…………………………………………………….

Cost: Free

Hours: Whenever the sun is up, I suppose

Food & Drink? The Land of Nod Winery is very close.

Children? Absolutely.

You’ll like it if: Even if you hate history, it’s a pretty spot

You won’t like it if: You were looking for different piglets and salamanders

Freebies: None

For the Curious:

The Friends of Beckley Furnace

Blackberry River Walks

Between the Lakes – a great resource for the area

More Beckley photos

Beckley chronology

Quarries out the wazoo

Check out the limestone quarry up the road

Interesting Read

Comment #1 on 06.30.14 at 7:42 pm